Twenty Years of Home Built Electric Car Adventures – A Three Part Series – Part II

It’s a good thing that I’m also good at the unexpected adventure, because I had some learning opportunities along the way. I’ll list three:

- Loose battery connections can get looser due to vibration and cause a thermal runaway situation. Basically, connection resistance causes heat, the heat increases resistance, and they feed on each other. The result is that you may end up with a melted battery post in the middle of traffic.

- Some older motor controllers use relays to facilitate regenerative braking and these can, very occasionally, stick. Again, in the middle of traffic.

- If you’re making your own motor controller, make sure you have a pre-charge resistor. I can’t stress this one enough! Repeat after me “pre-charge resistor”. https://www.diyelectriccar.com/forums/showthread.php/precharge-why-do-need-do-do-25419.html

Years went by and I still frequented the EV Trade’n Post keeping an eye out for parts, upgrades, and just generally feeling the pulse of the home brew EV world. One time, I found an excellent deal on a motor very similar to the one that was in the Bradley, only larger. I was very interested, not only because of the price, but also because some old EV’ers referred to this motor as the “Rolls Royce of electric car motors”. This sounded like a good deal and I knew that I would be building more EV’s in the future. The seller asked if I’d be interested in the adapter plate that came with the motor or the shaft adapter. He wouldn’t charge anything extra; I would only pay the extra shipping. Why the heck not? It then sat in my garage waiting for a new purpose in life.

I built a few human electric tricycles from junked bikes, an electric riding lawn mower/ snow blower, and a couple E-bikes in the intervening years.

Human Electric Recumbent Tricycle

My lead acid pack eventually died, and I had to park the car and burn dinosaur droppings (A.K.A. gas) like most other people for a while. At this time, I was working as an associate electrical engineer in Madison. My electric car naturally got noticed and people kept up to date with the various twists and turns of the project. One day, a close friend I worked with in engineering who knew of the battery pack’s demise offered to loan me money for a new battery pack. Not a lead acid pack, a lithium pack! This would be a total game changer. I thought “yea, right, too good to be true”. Also, there are numerous quotes in classical and modern literature about avoiding borrowing from friends.

“Neither a borrower nor lender be; For loan oft loses both itself and friend and borrowing dulls the edge of husbandry.” (Hamlet, Act-I, Scene – III)

Throughout the next two years he offered several times. One day he finally wore me down and I said, “Sure, why not.” To my astonishment, he wrote me a check then and there for the purchase of a new pack of lithium cells. I paid him back eventually, we are still good friends and collaborating on projects to this day.

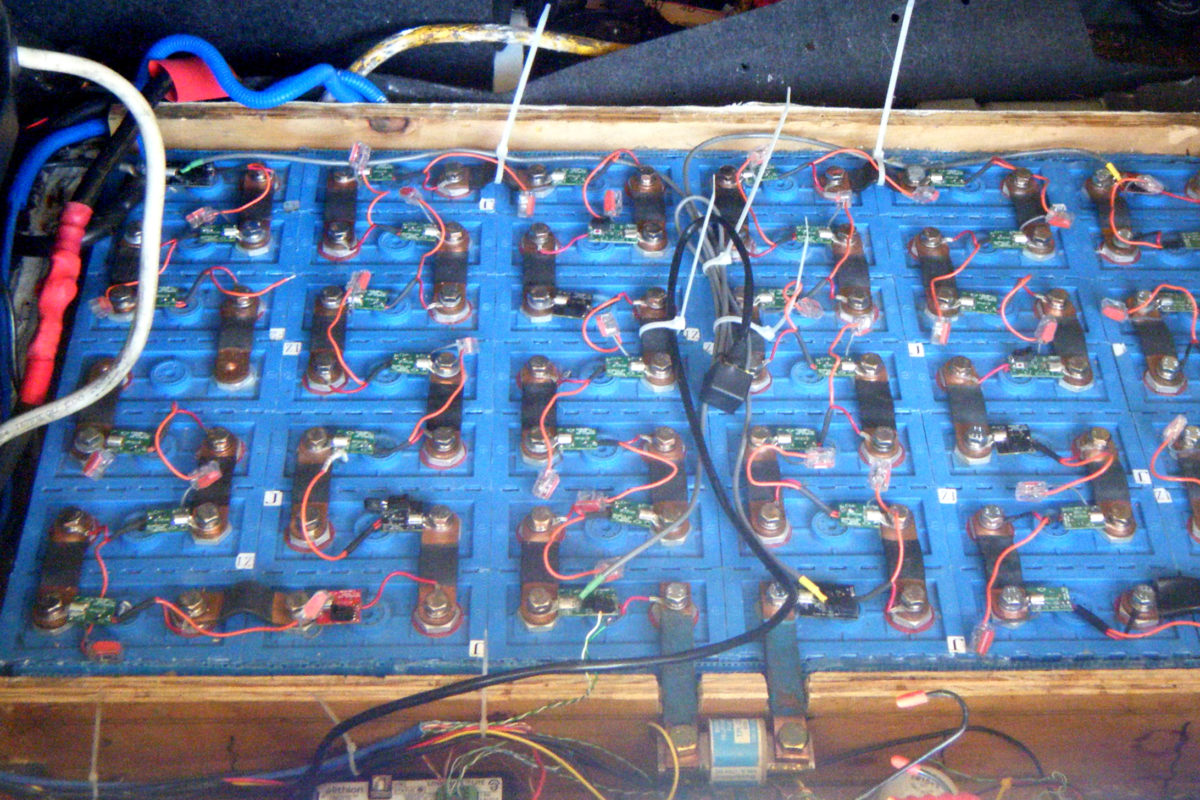

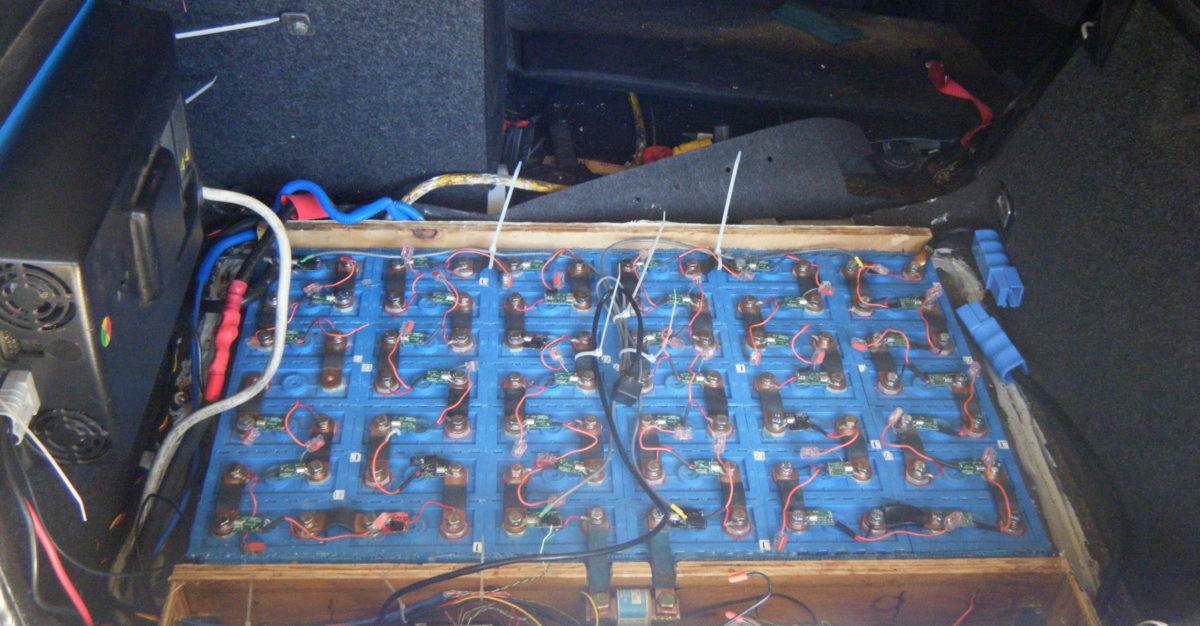

The new pack consisted of (42) 100Ah, LiFePO4, cells made by CALB (China Aviation Lithium Batteries, model# SE100AHA). Along with the batteries, a fancy new Battery Maintenance System had to be purchased. Unlike lead acid batteries, lithium batteries can be easily destroyed by even a momentary under or over voltage condition. If you’re spending thousands of dollars on batteries, you may as well spend another $800 to protect them. I installed these batteries in the Bradley and enjoyed the added benefits of enhanced performance and range. Now would be a good time to mention some battery pack safety tips. I have three basic ones that have served me well. Firstly, the one-handed rule. When you’re working with high voltage, it goes without saying that it can be potentially hazardous (potential is another term for voltage). To avoid electrical current going through your heart and ruining the day for all your loved ones, only use one hand when wrenching on any device with high voltage. The second tip is when wrenching on something with high voltage or current capability, wrap your wrench in tape or dip it in tool dip. If you are half as clumsy as I am, you may drop that wrench and then ZAP, POW, exciting stuff! In case anyone is wondering, I have never dropped a wrench in a battery bank. The third suggestion is basic: Caution is preferable to rash bravery.

This brings us to around 2009 when I was commuting to the Milwaukee School of Engineering, finishing my second bachelor’s degree. My 96’ Geo Metro wasn’t the best on the interstate and had more than 300,000 miles. The repairs were very time consuming, some of which deserve a Nobel prize (https://xkcd.com/1994/). These break down episodes, while providing a constant source of adventures, were taking what precious little time I had away from studying. I bought a larger car to make the commute safer, easier, and provide more time for proper attention to my studies. I purchased a 2000 VW Golf. It was wonderful for the cruise control alone, not to mention heated seats and other features. Almost immediately after buying the car, it started experiencing major wiring problems. The car would quit running anytime it rained, sometimes even on very humid days (don’t panic and make sure you know where your towel is). A VW mechanic I worked with knew of this common issue and suggested taking the car apart piece by piece and selling it because the main wire harness was just not worth replacing.

I liked the car, so instead, I converted it to electric.

Electric Vehicle #2

2000 VW E-Golf | The above picture is of the internal combustion engine being removed.

The battery bank, BMS, and charger were all taken from the Bradley and used in this conversion project. The Bradley went into storage, where it is to this day. A custom battery box was fabricated for the E-Golf which was placed in the spare tire storage area after removing some sheet metal. I built a new, more powerful motor controller capable of 144KW of pushing power. The motor I purchased years before from the EV Trade’n Post fit perfectly. Not only was the motor the right size, but the adapter plate, and motor shaft adapter were made for a VW Rabbit. Which is mostly the same as a VW Golf, lucky me. This conversion went quick and easy. I wish I had done it ten years earlier.

100Ah CALB Battery Bank

I drove the E-Golf around significantly more often than the Bradley. It was safer, easier to get in and out of and leak-free. Eventually, the 100Ah CALB cells were removed and replaced by cells which were lighter and cheaper. Finally, cheaper and lighter battery technology. Well, it turned out that there was a very good reason the new batteries were 60% lighter and cheaper. I performed a discharge test on one and discovered that they only had, you guessed it, 60Ah of the capacity (the batteries were advertised as 100Ah). One risk of doing business, I suppose. The car still worked fine but the new batteries left a bit to be desired. I thought that these 60Ah batteries would be great for a smaller vehicle. On a brighter note, the 100Ah CALB’s were put into service powering an off the grid home where they are currently today.

Tune in next week to find out what I did with the smaller batteries.