Does FEA seem unFEA$ible?

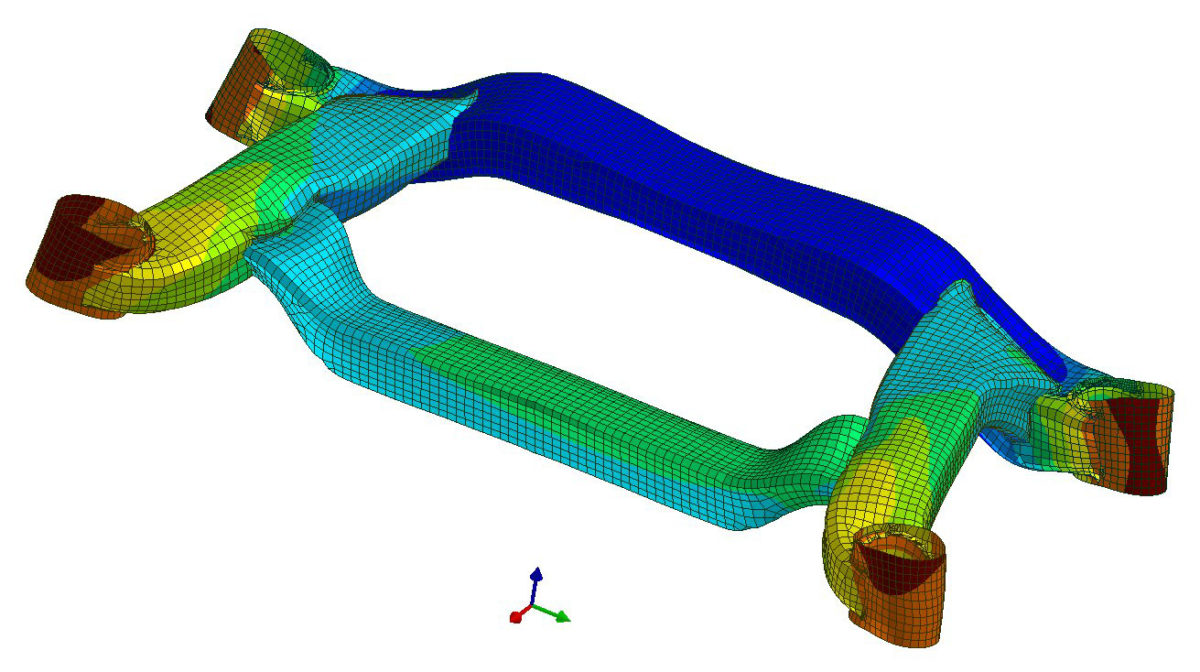

There is awesome power in computational analysis!

Most of the trial and error developing electronics, materials and parts can be avoided because computer models and sophisticated analyses can simulate so many physical operations and environmental conditions. Unfortunately, many small and medium-sized companies believe such analyses are too costly to justify.

“Not so,” says Dr. Feng Tian, Phd, Computational Analysis Specialist at bb7. “What engineers may not know, is there are methods of scaling-down FEA-like analyses.”

“Often the research scope is much greater than needed, and there are approaches to narrowing the focus to get critical results in less time. When compared to iteratively developing and testing prototypes, a focused FEA analysis may be more cost-effective.”

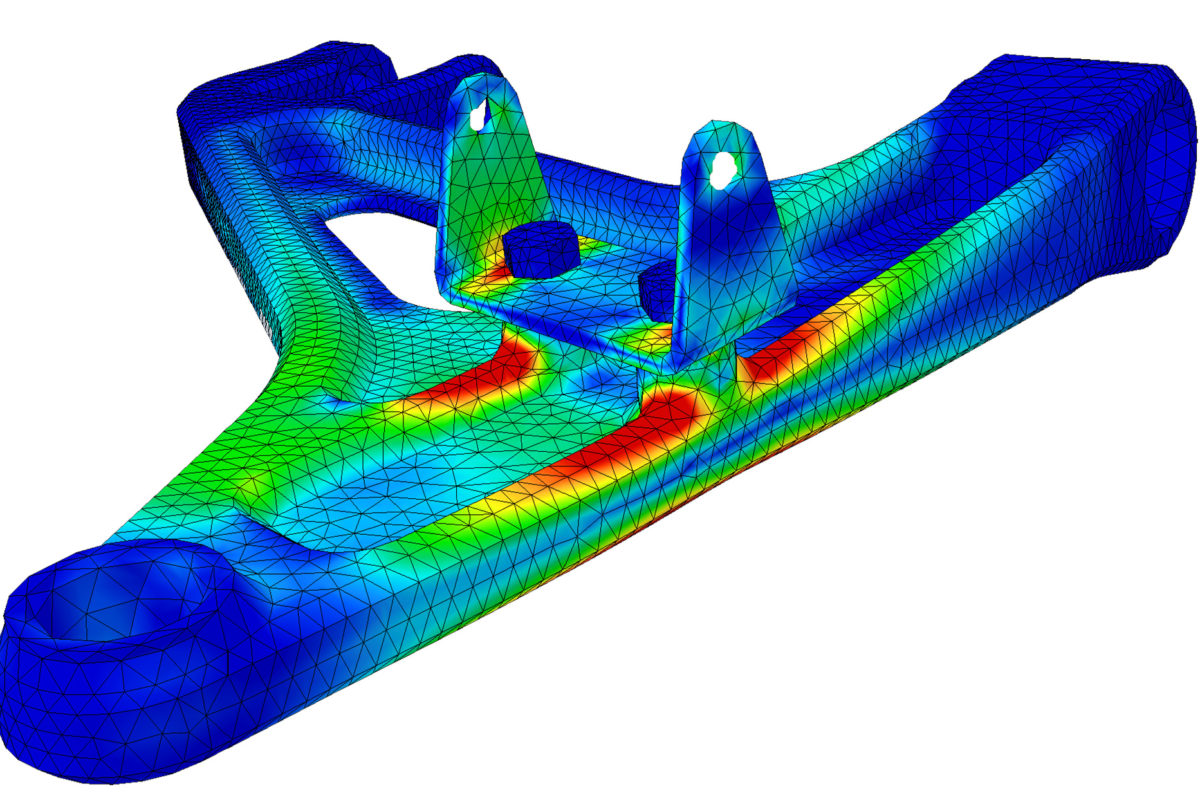

FEA-like software is becoming more accessible, and CAD software developers are adding analysis extensions to their tools.

Sometimes, elaborate analyses can be side-stepped altogether, because there are tools and methods that provide actionable data more affordably.

“Having the computational power of FEA at our disposal is wonderful,” says Tian “but because you have a pickup doesn’t mean you shouldn’t use a wheelbarrow when it will serve the purpose”.

Tian also cautions that having sophisticated software at your disposal is not the same as having the skill and background to use it.

FEA-like software is becoming more accessible, and CAD software developers are adding analysis extensions to their tools. But understanding the physics and the math underlying the analyses is critical to using such software properly.