Twenty Years of Home Built Electric Car Adventures – A Three Part Series: Part I

This blog post, originally intended to follow the progress of my current Electric Vehicle (EV) project, has evolved into a summary of EV projects spanning twenty years. I don’t claim to be an EV expert, but I do claim to have gumption and experience. In the following summary, I will hit some highlights.

If I were to pick a beginning, it would be when I was about six years old. I was in Boy Scouts and selling first aid kits around the small town where we lived. With the money, I bought a silver Porsche 911 remote control car. Not only was it wireless (at that time, remote-controlled didn’t necessarily mean wireless), but it also had a turbo lever! This is also when I started soldering, so I added in a small incandescent light to make the headlights functional. At some point, the garage door (aka my older brother) crushed the car. The car was gone, but my interest in electric vehicles continued full throttle.

Fast forward 12 years or so to when I finally bought my own computer and dial-up Internet. I started frequenting a website called the “EV Trade’n post”. Don’t bother looking for it; it no longer exists. It was a site for people to buy, sell or trade parts, including incomplete or complete home-brew electric vehicles. This led me to discover an 81’ Bradley GTE posted for sale.

Electric Vehicle #1: 81’ Bradley GTE Prototype

Electric Vehicle #1: 81’ Bradley GTE Prototype

This was one of five 81’ Bradley GTE prototypes. Only 50 GTE kits were sold in total. As I understand it, the story goes back to the late 70’s, when Bradley Automotive teamed up with General Electric to develop an electric kit car. To put it mildly, the battery technology at the time didn’t pack enough of a punch. Additionally, the Bradley Automotive company had some major quality issues. They filed chapter 11 and changed their name a couple times before finally going out of business in 1981. This prototype spent the next 10 to 15 years sitting in a car museum in Arkansas. I purchased the car from a private party, and after transporting it to my father’s house outside of Kingston, Wisconsin, I discovered that the carpet was so deteriorated that you could scoop it out with just your hand. I also discovered that the chassis pans were completely rusted through. This was obvious when my foot broke through the floor. The list of problems went on and on but let me just say that I basically bought a car body, transmission, title, and electric motor. Everything else had to be remade, repaired, or replaced. I’m exhausted just thinking about it.

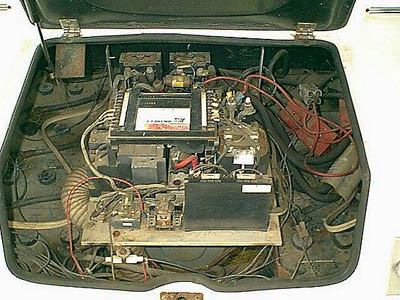

The original EV1 Forklift Motor Controller that never worked

The original EV1 Forklift Motor Controller that never worked

It took me about three years to get it roadworthy. It would’ve taken less time, but I was going to school full time and working overtime, so there wasn’t much spare time to drive an hour to my dad’s place to work on it in a farm shed. Half the time I spent cleaning so I could work on it. The shed where it was kept only had three walls, a roof, dirt/mud floor and no door. In total, I spent about ten years working on this car, on and off, while driving it.

It was fun to drive, and it drew attention, prompting many interesting connections and conversations. One example, I was driving it around Madison testing something or other when a couple in a red Prius started following me. When we reached a two-lane road, they pulled up next to me and yelled out the window, “Hey would you mind pulling over and talking to us about your car?”. The woman in the passenger seat turned out to be the person organizing Hybrid Fest 2006 at the coliseum that year. After talking about my project, a bit, she asked if I could bring it to Hybrid Fest.

The Bradley was not the only 100% electric car at Hybrid Fest that year, but it was the only one that was legal to drive on the road. UW Madison had an EV1, donated to them by General Motors, but they had to sign an agreement that the car could never be driven on any road ever! I spoke with some of the students about the car. Unfortunately, they didn’t know much about the inner workings, and all the work that was done to it was outsourced to an auto mechanic shop. I did, however, hear the comment that the lithium batteries were very “stiff”.

Allow me to explain what “stiff” batteries mean. At that time, I had ten 130 Ah deep-cycle lead-acid 12V batteries for the main battery bank. These were all strung together in series, providing in excess of 120 volts. When I stepped on the accelerator and my head slammed into the back of my seat as the car accelerated, the battery bank’s voltage would momentarily sag under this load. It would go from perhaps 130 volts down to maybe 90 volts during aggressive acceleration. A “stiff” battery pack, in this case, has two meanings. First, it would only have a small drop in voltage for the same power draw compared with my lead-acid bank. Second, as the batteries were depleted as the car was driven, the overall voltage would change little compared to lead-acid. Look at the discharge curves for lithium and lead-acid batteries and you’ll see what I’m talking about. Besides this “stiffness”, Lithium batteries have greater energy density, significantly longer cycle life, and are perfectly happy sitting partially discharged. Lead-acid batteries will degrade if left in even a partially-discharged state. I knew all these things, but I didn’t have thousands of dollars sitting in my back pocket for a sweet pack of lithium cells. I would soon find out that I didn’t need to.

Tune in next time to find out more about my adventures in home built electric cars.