During a Global Health Crisis, We Can Help with Sterilization and Disinfection

In a world where people are suddenly running short of hand sanitizer, my mind turns to hospitals and doctors’ offices, and the steps they need to take to make sure their tools and instruments are clean and ready for use. What do you know about sterilization and disinfection? We have learned a good deal through our work in medical device work here at bb7.

We’ve had to learn about non-woven fabrics when dealing with a client’s leaky sterilization container system.

In a different sterilization system, we needed to measure certain gas concentrations using light absorption – photometry. A couple of us with physics backgrounds made quick work selecting the wavelengths and path lengths, along with the surface finishes on parabolic path-folding mirrors.

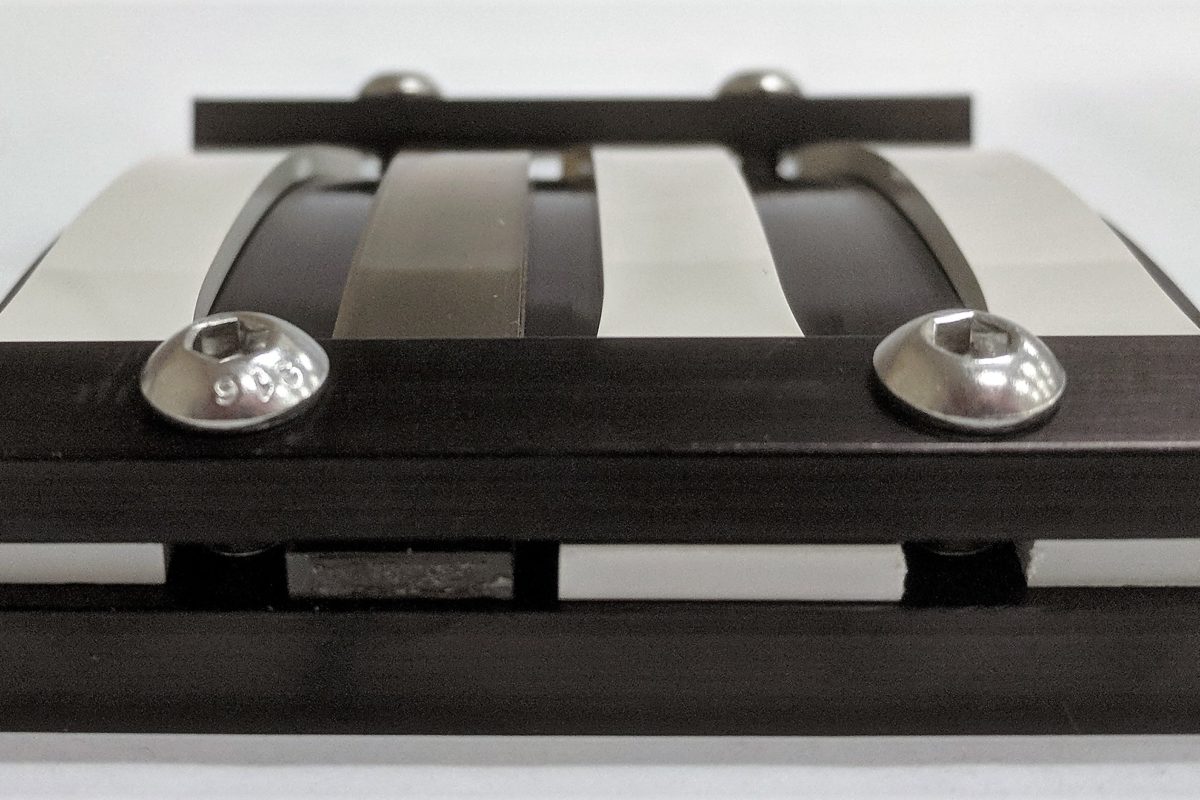

For another client developing a new line of sterilization containers, but suffering material fatigue issues in the harsh sterilization environment, we were able to do a careful design of experiments that allowed us to select a polymer for the vessel, but also to create a design that resisted stress concentrations. Our design highlighted our ability to combine our engineering and industrial design capabilities, which allowed us to develop significant usability improvements. One of my mechanical engineering colleagues here is one of the most creative designers I’ve ever worked with.

We’ve had teams observing processes in hospital central sterilization labs – large New York City hospitals, high throughput Midwestern hospitals, and in rural hospitals – as clinicians ready equipment for use in high risk environments. We’ve mapped the journey of equipment as it changes hands, gets transported, and is stored for use, and we understand the challenges and opportunities associated with keeping things disinfected and sterile along the way.

As with so much of what we do here, we like to take a systems approach when a client brings us a sterilization or disinfection challenge; everything affects everything else. Materials selection impacts design, impacts electrical design, impacts usability, impacts validation test protocols.

Riding on top of all of those considerations is perhaps the most important systems engineering factor – the flexibility, background, and creativity of the team doing the work. We are pretty proud of our team, as we are of the work our team has accomplished.