3D Printing & You: What to Expect from Consumer 3D Printing

3D printing technology continues to evolve rapidly, with new materials, methods and applications appearing every year. 3D printing might be a relatively new field, but it continues to revolutionize design, development, prototyping and manufacturing. It allows design iterations and customization to take place during “production.” Since there is no tooling and the machine can be reprogrammed with a new design anytime there is an update, it provides designers and engineers the ultimate in flexibility.

But what can we expect to see in the world of consumer 3D printing? It seems just yesterday consumers were lining up at exhibitions to see a “newfangled” 3D printer in action. Now, a 3D printer is “normal” technology in schools, libraries, labs, factories and, in some cases, homes. Psst: If you have yet to see a 3D printer in action, stop on by bb7! We’ll show you!

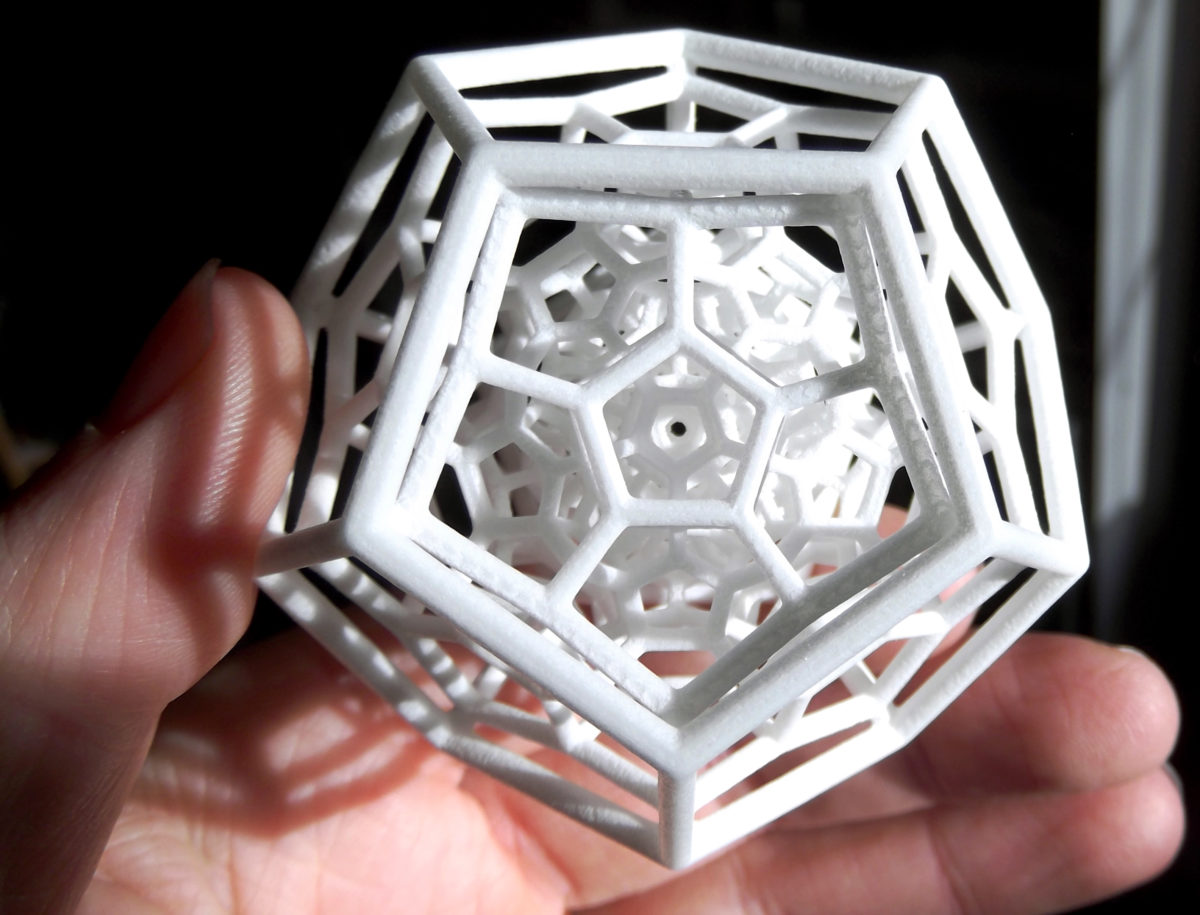

A 3D printed 120-cell polytope demonstrates 3D printing’s ability to create complex and intricate designs.

What can we expect in the next 20 years?

You will NOT have a 3D printer in your house in 20 years. Let me repeat that. You will NOT have a 3D printer in your house in 20 years….Unless you’re in the industry or you’re a 3D printing hobbyist. Sure, it’s exciting to imagine a future where a consumer prints his/her everyday objects or products. Need a paper clip? Print it! Break your soap dish? Print a new one! But, it doesn’t make any sense for the average consumer to have a 3D printer. The machines can be complicated to operate and require maintenance. The average consumer just won’t want to invest the time and money for the upkeep.

However, you will have many products that are custom made for you with 3D printing technologies.

In 20 years, custom products won’t just be for the rich and famous. The average consumer will be able to have their own custom watch, phone, shoes, clothes, car, house, you name it. This is where 3D printing will shine. The trend is already starting. Presently, elite athletes can buy custom fitted 3D printed shoes, helmets, bicycles and more. The cost is still high, but athletes either have the money or sponsors to pay for it. 20 years from now, this technology will be mainstream – accessible and affordable to most. You’ll be able to walk into your local running shoe store where they will take a scan of your feet to create a custom sole for the shoe you just designed. The shoes will be printed and ready in just a few minutes while you wait. Perhaps most stores will be outfitted with 3D printers.

Houses will also be 3D printed in 20 years. Basic concrete structures and bridges have already been printed.

This technology will advance to a state where a large machine will be assembled on your new home site to print the entire house. Electric, plumbing, and HVAC will be built-in and custom fit to exact needs and specifications. Not only will homes be more structurally sound, but they will be extremely energy efficient and last much longer. On top of all that, houses will be custom designed.

An interior view of Oak Ridge National Laboratory which combines clean energy technologies into a 3D-printed building and vehicle.

As 3D printing technology advances, consumers can expect more and more products customized to their needs. Shoes and homes just scratch the surface of future applications. More uses are being tested daily and, as the technology advances, the sky is literally the limit on where else it can be used.